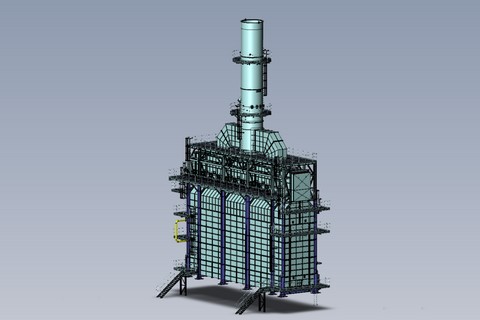

2 UNITS OF WHRS (WASTE HEAT RECOVERY SYSTEM)

2 units of WHRS of gas reforming plants belonging to a 5000t/day methanol synthesis plants; total 160 tons of seamless tubes OD42,4x3,6/3,2 SS 304H + finned tubes OD42,4x3,6 SA213 T11, headers OD406,4x32 304H + OD406,4x21,44 SA335 P11, interconnecting piping OD406,4x16,7 SS 304, refractory for Flue Gas Waste Heat Recovery System H-1002, total weight 520 tons

RADIANT COILS AND CONVECTION SECTION OF THE HEATER F2

mat. A335 P9/ A335 P5/ A312 TP304, refinery Slovnaft, MOL, Slovakia

DECARBONIZATION CYLINDRICAL FIRED HEATER OF DOW CHEMICAL PLANT IN STADE

mat.13CrMo4-5/X8CrNi25-21/S355J2, AD2000 Merkblatt, Air Liquide/Novargi, Germany

6 PCS OF PRIMARY + 6 PCS OF SECONDARY CYCLONES OF THE ETHANE CRACKER

mat. HRDOX/RELIA 400, WRS wear resistant material, weight aprx. 12t/pc, incl. FEA analysis, Antwerpen, T.EN, Belgium

FABRICATION OND ON-SITE ASSEMBLY OF FIRED HEATERS 3D-110, 3D-111, 3D-400 AND APH

mat. A376 TP347H, 13CrMo44, A335 P22, A335 P11, refractory, unit HyLube3, Puraglobe, Germany

CONVECTION COILS, INLET SYSTEM AND PIGTAILS, CONVECTION SECTION MODULES ASSEMBLY INCL. REFRACTORY INSTALLATION

mat. SA-106 Gr. B, SA-312 Gr. TP347H, SA-335 Gr. P11, total weight aprx. 300t, Assiut refinery Egypt, T.EN

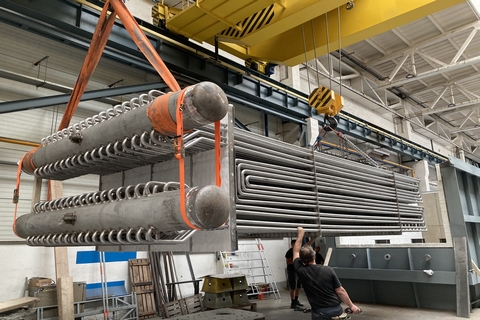

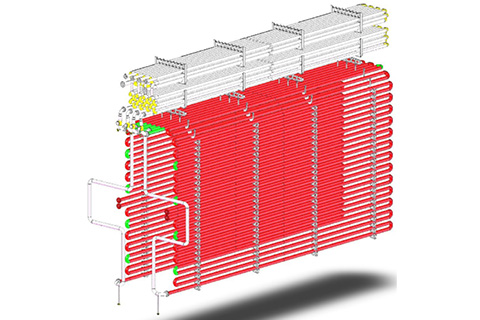

HP STEAM CONVECTION TUBE BANK INCL. HEADER BOX WITH REFRACTORY

mat. SA-106 Gr. B finned tubes, A335 P11, total weight 55t, S+C for Dow Chemical & YPF, Argentina

REFRACTORY LINED OUTLET HEADER OF HYDROGEN REFORMER PACKAGE

Ø 1016mm, L=16000mm, W = 26,5t, mat. A387 Gr.11/B409-N08810/A608/B564-N08811, Assiut refinery, T.EN, Egypt

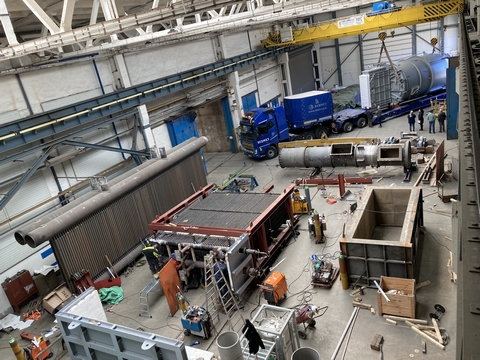

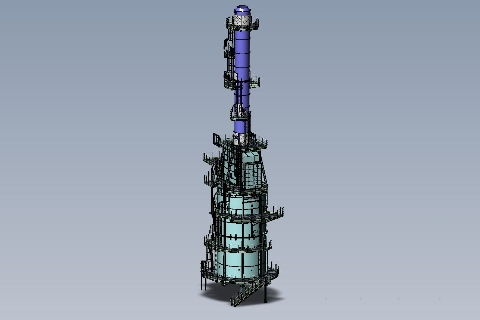

TPR (TECHNIP PARALLEL REFORMER)

OD = 2,4m, L = 23,5m, W: 150 t, material: SA387GR11/GR12, reaction tubes, refractory lined, ASME VIII. Div. 1./API 934/API 936, Technip Energies, India

REBOILER HEATER B202N

Reboiler heater B202N of hydrocracking unit, mat. S235JR, tubes ø168,3 x 7,11 A.W. - ASTM A312 TP 321, VE/WOOD/Petroineos Refinery, Lavera, France

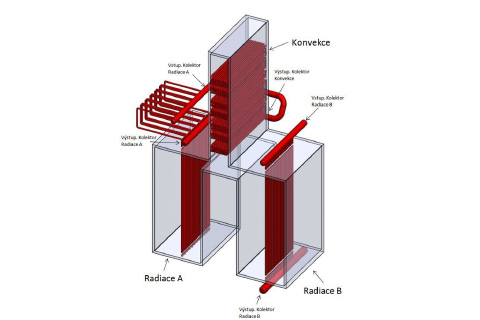

HEATER B-101

Revamp of heater B-101 of Styren III unit at SYNTHOS Kralupy, CZ, radiant coils: A - inlet manifold ø 457, 2 x 12,8 mm, A358Gr.304H, Centralloy tubes - HP40Nb+micro, outlet manifold ø 508 x 18 mm, Alloy 800HT + B - inlet manifold ø 508,13,2 mm, A358Gr.304H, tubes 88,9 x 6,35 mm Centralloy - HP40Nb+micro, outlet manifold ø 609,6 x 17,5 mm, Alloy 800HT; radiant coils operating temperature 900 – 1200 °C; convection: inlet manifold ø 406,4 x 12,7 mm, A106 Gr.B, tubes ø 88,9 x 5,49 mm, outlet manifold ø 457,2 x 12,8 mm, A358 Gr304H; cross-over piping: Alloy 800HT

ATMOSPHERIC HEATER 4-H01

Heater 4-H01 for PU-001 (25 x 7 x 40 m, 800 t) Crude Oil Distillation Unit with CDU No. 4 LPG Unit Basrah refinery, Iraq, tubes 8“SCH40 (219,1 x 8,18) A335 P9