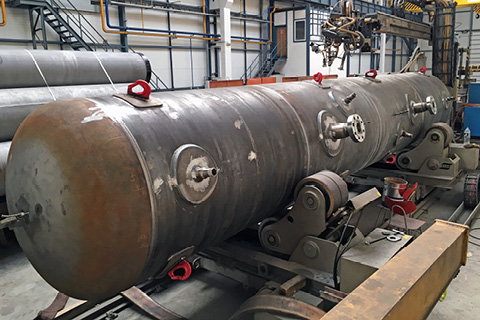

WELDING

Submerged arc welding (SAW) and plasma arc welding (PAW)

- min. Ø 750 mm

- max. Ø 5500 mm

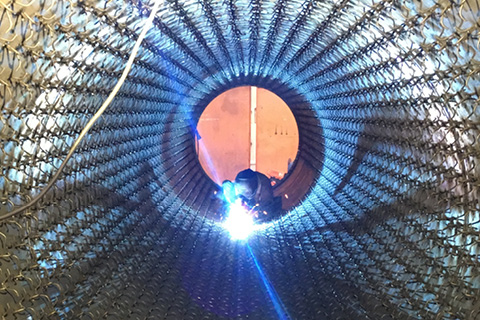

WIG/TIG

- plates, pipes and flanges 3 - 100 mm

- pipe outside Ø 16 - 800 mm

MIG/MAG

- conventional and pulse welding in shield gas

Electrode MMA, stud welding

- NELSON resistance stud welding from Ø 6 to Ø 14 mm

MACHINING

Horizontal boring and milling machines, drilling machines

- spindle Ø 160 mm

- X = 3150 mm, Y = 2300 mm, Z = 1600 mm

- clamping area 6000 x 4000 mm

- maximum load 20 t

Vertical lathe VTLD25 CNC (2018), SK 16, SK 12

- max. machining Ø 2 700 mm

- max. workpiece height 1 500 mm

- maximum load 12,5 t

Lathes

- max. machining Ø 620 mm

- max. L = 4500 mm

- maximum load 3 t

Plate edge planing - HHP 10 planing machine

- min. plate width 90 mm

- max. plate length 9 000 mm

- through height 90 mm

TUBE BENDING AND ROLLING

Hot rolling

- D 89 - 377 mm

- R min. 3 D but min. 450 mm

- R max. 2800 mm

- max. bend angle 180º

- max. wall thickness 23 mm

Cold bending

- D 16 - 108 mm

- R min. 3 D, max. 200 - 600 mm

- max. bend angle 180°

Cold bending

2023 AMOB CH 80 CN1 booster bending machine

- D 15 - 80 mm

- R min. 1 D

- max. bend angle 180°

- machine working length 14 000 mm

Cold rolling

- D 20 - 159 mm

- R max. unlimited, bend angle 360°

- max. wall thickness 8 mm

- tubes can be bent with the bend axis placed in more levels, as well as helically up to max. Ø 89 mm

MECHANIC AND PLATE FORMING SHOPS

Pre-bending - press HPC 250 TO

- max. die width 1 000 mm

- max. piston stroke 520 mm

- max. piston centre-to-housing frame depth 500 mm

Plate rolling

- max. plate thickness 45 mm

- width 3 000 mm

- max. Ø 5500 mm

Steel angles and profiles rolling

Press for panel straightening (max. load 350 t)

Cutting

- plasma, oxy-acetylene, saw, plate cutting

NON-DESTRUCTIVE TESTING

X-ray (RT)

Ultrasonic testing (UT), hardness testing (HT)

Magnetic testing, penetration testing, visual inspection (MT, VT, PT)

Positive material identification (PMI)

SURFACE TREATMENT, HEAT TREATMENT

Carbon steel blast cleaning

- blast room 4000 x 4000 x 10000 mm