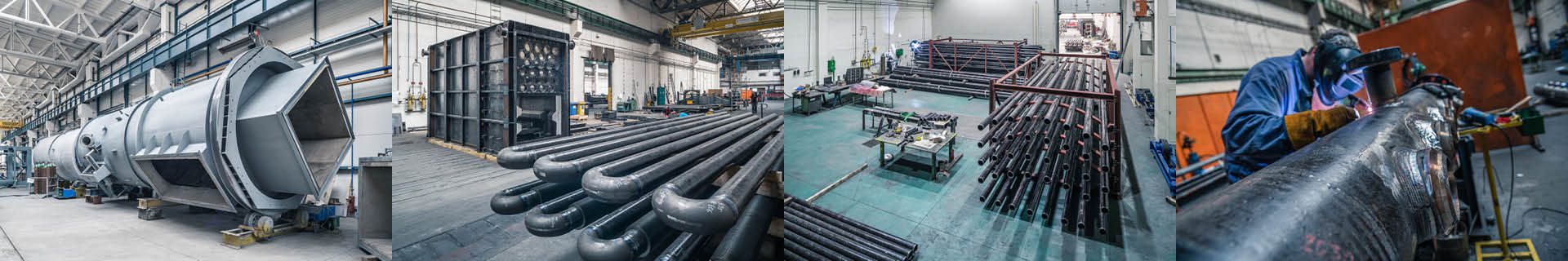

We fabricate fired heaters and related fired equipment for a wide range of applications in refinery, oil, gas and petrochemical industries.

MBNS with extensive experience supplies licensed proprietary equipment in fired heaters, transfer line equipment and reactors for a range of applications in processing of hydrogen, ethylene, biochemical, refining and fertiliser (refinery, oil, gas and petrochemical industry). These are frequently Refractory lined.

Vertical cylindrical heaters with radiant vertical coil

These heaters are the most commonly used. In the radiant section, tubes stand or hang vertically, in a circle around the floor-mounted burners. Firing is parallel to the radiant section tubes. Vertical-cylindrical heaters can be designed both with and without a convection section. The all-radiant heater is less expensive, but characterized by low efficiency. This kind of design is typically suitable for process services as Reboilers, Hot Oil Heaters, Heat Transfer Medium Heaters, Feed preheaters, Regeneration Gas Heaters and Light Crude Heaters.

Vertical cylindrical heaters with helical coil

These heaters are characterized by a sub-horizontal coil arrangement. The coil is arranged as a spiral (helical coil) along the cylindrical firebox wall. The burners are floor-mounted and firing upwards. The process flow direction in the radiant coil can be either upwards or downwards (according to the desired process flow regime). These heaters can be designed both with and without a convection section. The main advantages of this kind of heaters are the possibility to drain completely the coil by gravity; the low pressure drop (if compared with a standard vertical cylindrical heater), the reduced plot area requirement and the flexibility in tube spacing allowing the reduction of peak heat fluxes (where required). This kind of heater combines the advantage of vertical-cylindrical heaters with the horizontal tube heater arrangement and is typically suitable for process services such as Reboilers, Hot Oil Heaters, Heat Transfer Medium Heaters, Feed preheaters, Regeneration Gas Heaters and Light Crude Heaters.

Cabin Heaters

This kind of design is widely used for services requiring horizontal tube arrangement (for specific flow pattern requirement). In the radiant section (cabin shape) the tubes are arranged horizontally along the sidewalls and the sloping roof of the cabin (on the front wall no tubes are installed). The firebox can be composed by a single cabin cell or double cells according to the size and number of passes. Typically the convection section extends over the entire length of the radiant section. Horizontal tube arrangement requires higher plot area (for tube extraction) but allows coil drainability (by gravity) and easier access to radiant return bends (seldom located inside radiant header boxes) for inspection and maintenance purposes. Burners are floor-mounted, installed in a row placed in the centre-line of the cabin and fired vertically. Thus, firing is generally normal to both radiant and convection tubes. Sometimes, with small duties, burners are instead located in the front walls opposite side firing horizontally toward the centre of the firebox. This kind of design is typically suitable for Topping and Vacuum services, Crude Heaters, Reboilers, Heavy Feed preheaters.

Box heaters with Vertical Radiant Coil (single/double fired)

This kind of heaters is the most commonly used for very large duties. In the radiant section, tubes stand vertically along all four walls and across the firebox (dividing the box in different cells). Tubes on the walls are fired from one side (as for vertical-cylindrical and cabin fired heaters) while tubes running across the box are fired on both sides by the floor-mounted burners. The possibility to add “two-side fired” tubes shortens the radiant coil and results in a significant decrease in radiant box volume, compared to horizontal tube cabin heaters and in the possibility to reduce the peak heat flux as required. Each tube pass has an equal number of both walls and centre tubes passes in order to keep as uniform as possible the heat distribution between the passes.

The convection section extends over the entire (or almost the entire) length of the radiant section. This kind of design is typically suitable for process services such as Topping and Vacuum services, Reboiler, Heavy Feed preheaters, Hydrocrackers, Visbreakers and Cracking. Process feeds are generally 100% liquid, or vaporizing services.

WHAT DO WE OFFER:

We also fabricate spare parts and fired equipment for reconstructions and modernizations of existing heaters and plants such as:

- Coils - radiant, convection, helical etc.

- Convection modules

- Pre-heaters

- Stacks

- Steel structures

- Effluent chambers, inlet/outlet manifolds, transferlines (TLE), refractory lined outlet headers, mixed feed inlet headers, distributors, cross-overs, riser heads

- pigtails

- piping and ducts

MATERIALS:

The company does use advanced technologies in welding, hot and cold forming, heat treatment and testing of relevant materials as generally used for above mentioned equipment:

- High Alloy steels alloyed high percentage with of Nickel (2-20%) and Chromium (0,5-18%) specifically elements to develop corrosion resistance or extreme temperature stability

- (low) Alloy steels alloyed frequently Chromium-Molybdenum used grades P2, P12, P11, P22, P22L, P21, P21L, P5, P9 and P91

- Stainless steels (chromium, chromium-nickel, and chromium-manganese-nickel stainless steel) alloyed with Titanium, Molybdenum, Nobium, according ASTM grades of group SA 240/240M, according SAE designation series 300 (austenitic chromium-nickel stainless steel), 400 (ferritic and martensitic chromium stainless steel)

- Nickel alloys (INCOLOY® Alloy 800 H / HT. 1.4876 / 1.4958 / 1.4959. UNS N08810 / UNS N08811)

- Carbon steels

EQUIPMENT:

- Refinery and petrochemical heaters

- Topping heaters

- Vacuum heaters

- Reboilers

- Reactor charge heaters

- Catalytic reformers and platforming

- Hydrocracking

- Start-up heaters

- Gas Regeneration heaters

- Hot oil heaters

- Oxygen and gas heaters

- Steam superheaters

- Heaters for preheating of steam

- Reaction heaters

- Visbreaking

- Thermal cracking

- Coking

- Steam reforming heaters for ammonia, methanol, hydrogen plants on the basis of process design of licensors

- Ethylene cracking heaters on the basis of process design of licensors

- Waste heat recovery units (WHRU)

- Waste heat boilers on heaters

- Waste heat boilers on steam reformers

- Heat recovery steam generation units

SPECIFIC REQUIREMENTS APPLICABLE:

- API RP 934 for Cr-Mo materials

- API 936 RP for Refractory Lining

- ASTM A-262